Welcome to the world of tire heat maps! If you’re new to this concept, you’re in for an enlightening journey. A tire heat map is a visual representation that shows the temperature distribution across a tire’s surface. This tool is invaluable for anyone looking to optimize vehicle performance, enhance safety, and extend tire lifespan. Understanding tire heat maps can significantly help in identifying problem areas, such as uneven tire wear or improper inflation, which can lead to more severe issues if left unaddressed.

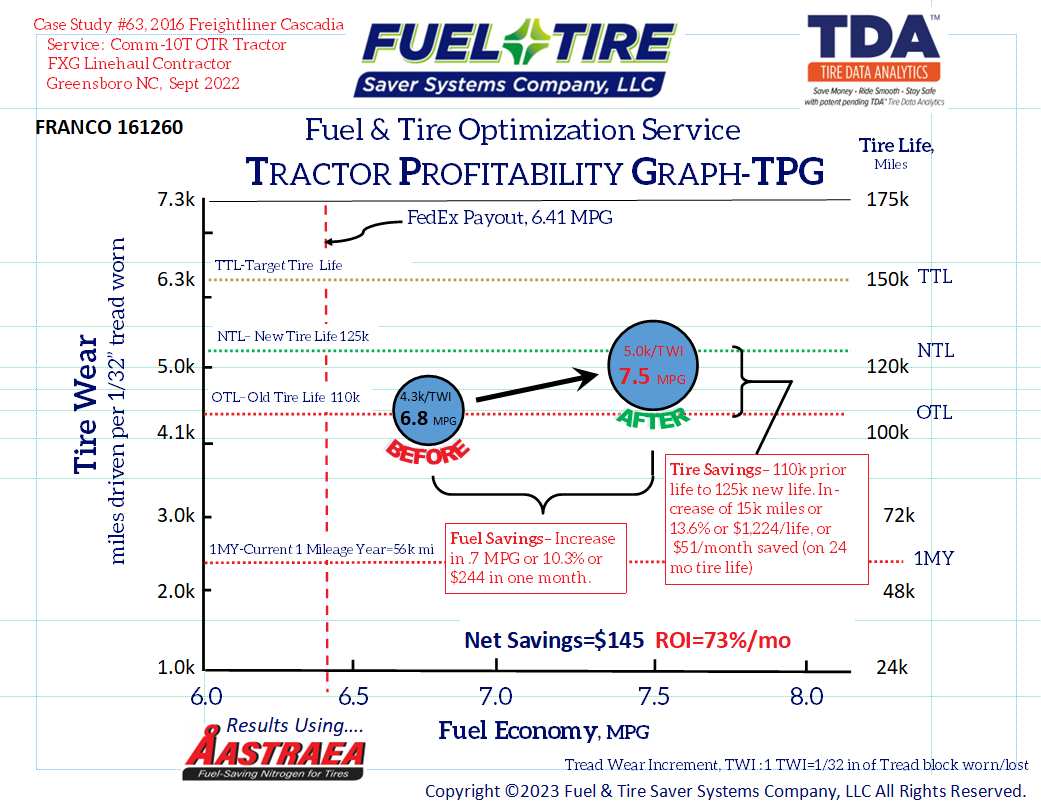

Incorporating tire heat maps into regular fleet maintenance routines can result in substantial savings. By pinpointing specific areas where the temperature is higher, fleet managers can take proactive measures such as rotating tires, adjusting air pressure, or identifying alignment issues. This not only helps in saving fuel but also in extending the overall life of your tires, making your fleet more efficient and safer on the road.

Are you ready to optimize your fleet’s performance with tire heat maps? Request Fleet Pricing, contact our office at (703) 429-0382, or email Mike.LoPresti@fuelandtiresaver.com to get started today!

Table of Contents

ToggleHow Tire Heat Maps Work

Tire heat maps operate on a relatively straightforward principle: they utilize thermal imaging technology to capture the temperature distribution across the surface of a tire. This data is then translated into a visual map using different colors to represent varying temperature ranges. Typically, cooler areas are shown in shades of blue and green, while warmer regions are depicted in red and yellow. This visual representation allows for easy identification of temperature anomalies across the tire’s surface.

The process begins with the use of infrared cameras or thermal sensors that scan the tire while the vehicle is in motion or immediately after use. These devices detect infrared radiation emitted by the tire and convert it into an image that reveals the temperature profile. Advanced software then processes this data to generate the heat map, which can be analyzed for potential issues.

Interpreting these maps requires a keen understanding of tire dynamics. For instance, a consistently high temperature in a specific area could indicate an alignment issue, excessive friction, or under-inflation. Conversely, cooler spots might suggest over-inflation or lack of adequate contact with the road surface. By analyzing these patterns, fleet managers can make informed decisions to rectify any issues, thereby enhancing overall vehicle performance and safety.

Benefits of Using Tire Heat Maps

Utilizing tire heat maps offers numerous benefits that extend beyond mere temperature monitoring. One of the primary advantages is the enhancement of vehicle safety. By identifying abnormal heat patterns, potential tire failures can be detected early, reducing the risk of blowouts and accidents. This preemptive approach ensures that tires are always in optimal condition, providing a safer driving experience.

Another significant benefit is improved fuel efficiency. Tires that are properly maintained and free from issues such as misalignment or improper inflation contribute to lower rolling resistance. This, in turn, leads to less fuel consumption, which is especially critical for fleet operations where fuel costs can significantly impact the bottom line. A well-maintained fleet can see substantial savings in fuel expenses over time.

Additionally, tire heat maps contribute to extended tire lifespan. By regularly monitoring the temperature distribution, it’s easier to identify and address issues that could lead to uneven wear. This proactive maintenance helps in maximizing the life of each tire, reducing the frequency and cost of replacements. Over time, this can result in considerable savings for fleet operators.

Moreover, using tire heat maps is also an environmentally friendly practice. With improved fuel efficiency and extended tire life, the overall carbon footprint of vehicle operations is reduced. This aligns with the growing emphasis on sustainability and responsible resource use in the transport industry.

In summary, the adoption of tire heat maps provides a comprehensive approach to tire management that enhances safety, boosts fuel efficiency, prolongs tire lifespan, and supports environmental sustainability.

Tire Heat Maps and Fuel Efficiency

One of the most significant impacts of tire heat maps is on fuel efficiency. By closely monitoring the temperature distribution across tires, fleet managers can gain valuable insights into how well their tires are performing. When tires are properly inflated and aligned, they generate less heat, which is an indicator of lower rolling resistance. Lower rolling resistance means that the vehicle requires less energy to move, thereby consuming less fuel.

In contrast, tires that are under-inflated or misaligned tend to overheat, which increases rolling resistance and, consequently, fuel consumption. Tire heat maps can quickly identify such issues, allowing for prompt corrective actions. This proactive approach ensures that all tires are maintained in optimal condition, directly contributing to improved fuel efficiency.

Another way tire heat maps enhance fuel efficiency is through the detection of irregular wear patterns. Uneven wear can lead to increased friction and higher fuel consumption. By using heat maps to spot these irregularities early, fleet managers can schedule timely maintenance, such as tire rotation or alignment adjustments, to prevent excessive fuel usage.

Moreover, tire heat maps facilitate better load management. Overloaded tires tend to overheat, which not only compromises safety but also reduces fuel efficiency. By regularly analyzing heat maps, fleet operators can ensure proper load distribution, thereby optimizing fuel consumption.

In essence, tire heat maps serve as a critical tool for maximizing fuel efficiency. By ensuring that tires are always in their best condition, these maps help fleets save on fuel costs, reduce environmental impact, and enhance overall operational efficiency.

Implementing Tire Heat Maps in Fleet Management

Integrating tire heat maps into fleet management systems offers a robust solution for enhancing vehicle performance and safety. The first step in implementation involves selecting the right technology. Modern tire pressure monitoring systems (TPMS) often come equipped with thermal sensors that can provide real-time data on tire temperatures. These sensors relay information to a centralized system where it can be analyzed and visualized as heat maps.

Once the appropriate technology is in place, the next crucial step is to train the personnel responsible for monitoring and maintaining the fleet. Technicians and fleet managers should be well-versed in interpreting heat maps, understanding the significance of different temperature patterns, and knowing the appropriate corrective measures to take. This training ensures that the data provided by tire heat maps is effectively used to maintain optimal tire conditions.

Additionally, implementing tire heat maps requires establishing a routine monitoring schedule. Consistent data collection is vital for identifying trends and making informed decisions. Daily or weekly checks can help catch issues such as under-inflation, misalignment, or irregular wear before they escalate into more significant problems.

Data integration is another critical aspect. The information from tire heat maps should be integrated with other fleet management software to provide a comprehensive overview of vehicle health. This holistic approach allows for better decision-making and more efficient maintenance scheduling.

Furthermore, fleet managers should consider leveraging predictive analytics. By analyzing historical data from tire heat maps, predictive algorithms can forecast potential tire failures or maintenance needs, allowing for preemptive actions that save time and resources.

In summary, implementing tire heat maps in fleet management involves a combination of the right technology, trained personnel, routine monitoring, data integration, and predictive analytics. This comprehensive approach ensures that fleets operate more efficiently, safely, and cost-effectively.

Future of Tire Heat Mapping Technology

The future of tire heat mapping technology is brimming with potential advancements that promise to revolutionize fleet management. One of the most exciting developments on the horizon is the integration of artificial intelligence (AI) and machine learning (ML) algorithms. These technologies can analyze vast amounts of data from tire heat maps to predict wear patterns, detect anomalies, and recommend proactive maintenance strategies.

Another promising advancement is the enhancement of sensor technology. Future sensors will likely be more accurate, durable, and capable of providing real-time data with minimal latency. These improvements will enable more precise monitoring of tire conditions, allowing fleet managers to make data-driven decisions quickly.

Connectivity will also play a significant role in the evolution of tire heat mapping technology. The advent of 5G networks will facilitate faster and more reliable data transmission between sensors and central management systems. This connectivity ensures that fleet managers receive up-to-the-minute information, enabling them to respond promptly to any issues.

Moreover, advancements in big data analytics will allow for more comprehensive analysis of tire performance across entire fleets. By aggregating and analyzing data from multiple sources, fleet managers can gain deeper insights into overall fleet health, identify long-term trends, and optimize maintenance schedules more effectively.

Another area of innovation is the integration of tire heat mapping data with other vehicle systems. For instance, combining tire data with engine performance metrics and driver behavior analytics can provide a holistic view of vehicle health and identify areas for improvement. This integrated approach leads to more efficient operations and reduced costs.

In the coming years, we can also expect tire manufacturers to play a more active role in the development of heat mapping technology. Collaborations between tire makers and tech companies could lead to the creation of tires with built-in sensors and other advanced features, further enhancing the capabilities of tire heat maps.

With these advancements on the horizon, the future of tire heat mapping technology looks promising. Fleet managers who adopt these innovations will be well-positioned to enhance safety, improve efficiency, and reduce costs. Request Fleet Pricing by visiting our contact page, calling our office at (703) 429-0382, or emailing Mike.LoPresti@fuelandtiresaver.com.